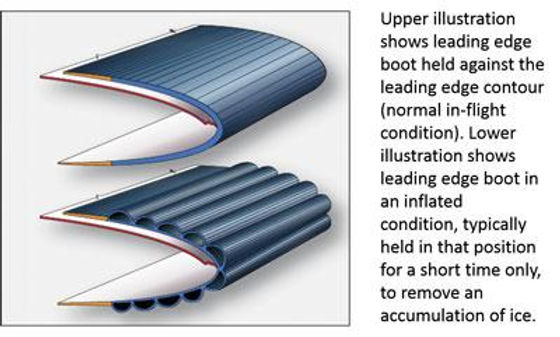

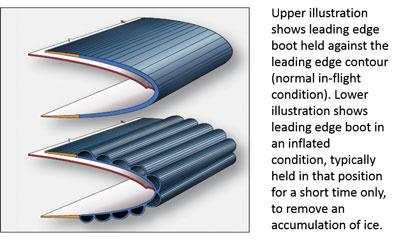

Looking at liquid in-flight de-icing systems, how they perform, technical specifications for systems offered by CAV Systems. To understand the application of de-icing technology, the 100-year old history will be covered and a few performance studies will be presented. Many exciting technologies have come forward that have specialized applications for different aircraft classes.Click the section header to jump to the section:De-Icing Technologies On the MarketOn the market today, most aircraft have installed one of four different types of de-icing mechanisms:Pneumatic De-Icing Boots Work on the de-icing boots began in 1930 when William C. Geer, PhD, took notice of more frequent air-mail aircraft crashes. Initial design intent used a rubber seal as the foundation for the system, soon followed the need to deform the leading edge airfoil to expand the ice sheet that formed. After further design and testing the final version of the de-icing boot functioned by inflating the leading edge up to 18psi which begins to break away accumulated ice sheets (Piper Flying). The photo below show a before and after of a modern day de-icing boot on a leading edge:De-Icing Boot on Leading Edge. 1. Piper FlyingLiquid De-Icing Systems Installing a liquid de-icing system on your aircraft does involve more moving parts and requires a reservoir of liquid placed within the aircraft substructure, but this system has a cost and operational benefits compared to other systems. Surprisingly, CAV Systems is one of the only liquid de-icing products on the market. CAV Systems highly-engineered technology sprays a bio-degradable fluid through a custom-fitted porous leading edge on the control surface which is spread across the surface of the components from the oncoming airflow (CAV Systems Leading Edge). The photo below shows the leading edge with thousands of perforated holes which allow the de-icing fluid to spray out from:Leading Edge with Perforated Holes. 2. CAV Systems Leading EdgeHeated Bleed Air System The heated bleed air de-icing system is the most passive type of technology on the market today. To operate, the pilot flips a switch and a duct channels hot air from the engine in the substructure of the aircraft ie. wing leading, rudder, etc. A few negative effects of this system are that odor and contaminates from the engine could make their way into the cabin of the aircraft and that there can be a delay between when bleed air is turned on and when the leading edge of the aircraft heats up enough to melt the ice (Aerocorner). In order for bleed air de-icing systems to be efficient the engines need to produce enough heat and pressure typically found only in jet-turbine engines; this limits bleed air systems to non-piston powered aircraft (SKYbrary Bleed Air Systems). Thermal De-Icing System Our final de-icing system on the market is the thermally heated leading edge method. There are two types of setups for this method 1). evaporative heating and 2). leading edge warming. The first requires an immense amount of energy to fully evaporate water preventing it from refreezing further down along the airfoil and the second warms the water enough to prevent it from freezing on or near the leading edge (SKYbrary Aircraft IPS, Spinoff NASA). How Well Do Liquid De-Icing Systems Work? So far, the pros and cons of different de-icing systems have been sprinkled here and there, but we are going to tabulate different technical specs of all four types to show which de-icing system would be right for your aircraft or aircraft design project.SE around 40lb + 70lb for fluidaround 42k (Aviation Consumer)cost for APU duct and electronics30k(Aviation Consumer Thermawing)general maintenance for enginearound 11k for replacement$30/gal but less with bulk order** a regional jet would be every 3-4 years and best case would be 20 years for an aircraft that is hangared for most of its life and used very infrequently (Aviation Consumer). CAV Systems approximates a replacement window for boots to be 5-10 years (CAV Systems Ice Legal). CAV Systems Liquid De-icing System The CAV Systems TKS has much to dive into, but we are going to start by explaining how it works. How CAV Systems TKS Works A formed titanium plate is shaped for the airfoil specific to the aircraft and has around 800 holes laser perforated into it in the normal direction. The substructure of the aircraft is fitted with tubes, pumps, and resevoirs that feed fluid into the leading edge and provide enough pressure to push the fluid through the 0.0025in diameter size holes to the ambient atmosphere. As the fluid accumulates on the leading edge of the surface, the natural laminar flow spreads the fluid across the entire surface to full remove ice and drop the freezing temperature of water to -76F. Key benefits of the CAV Systems TKSand below is the list of items to be discussed:only Ice Protection System that can provide complete ice protection for the full flight envelope.adds no additional drag to the aircraft.corrosion resistant titanium leading edge panelprovides protection for propellerSystem is rated to last the lifetime of the aircraft Based on the compiled table in the previous section, the control offered by the TKS system and lifetime use of the system surpass all other technologies on the market for in-flight de-icing aircraft surfaces. Currently there are around 8000 aircraft using the TKS system and about 35% of aircraft without any Ice Protection System, so much of the market is available for technologies like these. ReferencesPiper Flying (2023), “Accumulating Knowledge: De-Ice Boots,” https://www.piperflyer.com/maintenance-technical/1149-accumulating-knowledge-de-ice-boots.html?jaredirectCAV Systems Leading Edge (2023), https://www.cav-systems.com/design-consulting/ice-protection-design/Aerocorner (2023),”How it works: Bleed Air System,” https://aerocorner.com/blog/bleed-air-system/Skybrary Bleed Air Systems (2023), “Aircraft Bleed Air Systems,” https://www.skybrary.aero/articles/aircraft-bleed-air-systemsSkybrary Aircraft IPS (2023), “Aircraft Ice Protection Systems,” https://www.skybrary.aero/articles/aircraft-ice-protection-systems Spinoff NASA (2007), “Deicing System Protects General Aviation Aircraft,” https://spinoff.nasa.gov/Spinoff2007/t_5.htmlAviation Consumer (2019), “Boot Replacement: Minimal Competition,” https://www.aviationconsumer.com/maintenance/boot-replacement-minimal-competition/ Marlin Wire (2020), “Your Guide to Jet Engine Maintenance,” https://www.marlinwire.com/blog/your-guide-to-jet-engine-maintenance#:~:text=On%20average%2C%20a%20full%20overhaul,%2D%24300%20thousand%20per%20engine.Aviation Consumer Thermawing (2019), “Retrofit De-Icing: ThermaWing Impresses,” https://www.aviationconsumer.com/uncategorized/retrofit-de-icing-thermawing-impresses/CAV Systems Retrofit (2023), “Retrofit,” https://www.cav-systems.com/tks/retrofit/CAV Systems Ice Legal (2021), “Is your aircraft ice legal?,” https://www.cav-systems.com/news/is-your-aircraft-ice-legal/#:~:text=The%20more%20resistant%20a%20system,every%20five%20to%20ten%20years.