An encounter with inflight icing can be deadly for any aircraft. Ice detectors, installed on many transport aircraft, provide critical icing information to the flight crew and aircraft ice protection systems.

Aircraft Ice Detection

How does an ice detector work?

Collins Aerospace manufactures many of the ice detectors installed on airliners, small jets, and turboprop aircraft.

The Collins Aerospace vibrating probe ice detector consists of a housing, mounting plate, wing-shaped strut, and a small probe. The device looks simple enough from the outside, but uses some interesting physics to do its job.

Collins Vibrating Probe Ice Detector

An electric current induces the probe to resonate (vibrate) at a specific ultrasonic frequency. Ice accumulation on the probe causes the resonance frequency to decrease. Detector logic senses the change in frequency and triggers a crew advisory or, in an automatic system, signals ice protection systems to activate.

During icing conditions, the probe’s internal heater cycles on and off to clear ice accumulation. The sampling and heating cycle allows the detector to continuously sense (and in some detectors, measure) ice accumulation.

Was the 1966 Beach Boys hit “Good Vibrations” inspired by the vibrating probe ice detector?

Ice Sensor Certification

Collins Aerospace produces sensors that fall under three certification types.

1. Primary Automatic

The ice detector is part of an automated ice protection system. Using signals from the ice detector, the system automatically activates aircraft ice protection systems when needed. An automatic system improves fuel efficiency and reduces wear on moving parts. Best of all, the primary automatic system reduces pilot workload.

2. Primary Manual

The ice detector alerts the crew when protection is required. The flight crew then activates ice protection manually.

3. Advisory

The flight crew activates ice protection based on guidance from the aircraft manufacture and/or company. The ice detection system provides an alert as a back-up to the established crew procedures.

Advisory systems require crews to be proactive and activate ice protection systems when conditions are favorable for icing.

Icing tastes better on cookies

767-300F Ice Detector

The Boeing 767-300F ice detector is located on the right side of the aircraft nose, below the first officer’s window and pitot tubes.

The 767 freighters that I fly have a Collins advisory ice detection system. The detector activates an EICAS message (ICE DET ON) to alert the crew of ice accumulation.

When the sensor is free of ice, the EICAS advisory changes to ICE DET OFF. The crew continues to use ice protection until clear of potential icing conditions.

767-300F EICAS screen (Engine Indication and Crew Alerting System)

ICE DET ON alert when detector senses ice

ICE DET OFF alert when detector is clear of ice

When is ice protection used?

An advisory ice detection system serves as a final warning to alert the crew that ice protection is needed. In most cases, the flight crew activates ice protection before receiving an alert from the ice detector.

Airlines develop procedures for operating ice protection systems based on recommendations from the aircraft manufacturer. Here are examples of procedures for Engine Inlet Cowl ice protection:

Ground Use

Engine Inlet ice protection shall be selected ON in visible moisture when outside air temperature (OAT) is ≤10°C.

In-Flight Use

Engine Inlet ice protection shall be selected ON in visible moisture between 10°C TAT (total air temp) and -40°C SAT (static air temp).

767-300 ice protection panel. Crew has switched on left & right engine anti-ice. Amber ICING alert indicates the ice detector senses ice.

If the crew follows the above procedures, they will activate engine ice protection before receiving an alert from the ice detector.

What about wing ice protection?

The button labeled “WING” on the Anti-Ice panel activates wing protection. The 767-300 wing anti-ice system uses engine bleed air to heat the three outboard leading edge slats on each wing.

Boeing engineers did not include ice protection on the inboard wing leading edge slats. Ice buildup in these areas does not significantly impact performance. I’ve flown approaches and landings with ice on the unprotected areas and the aircraft flies beautifully.

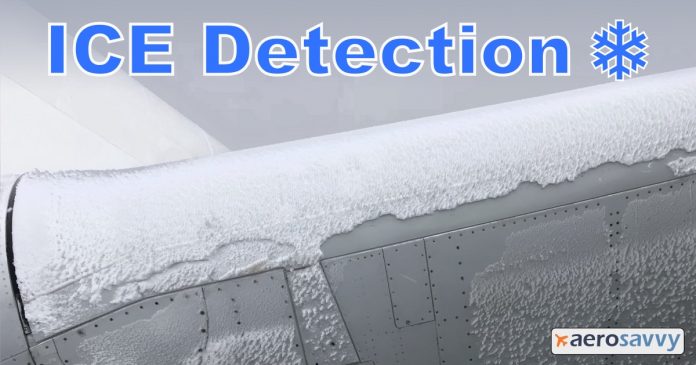

Rime ice on the unheated, inboard portion of a 767 wing. The ice accumulated during approach to Anchorage, AK.

Pilots typically use wing protection when ice begins to accumulate on window frames or windshield wipers (used as de-ice, after accumulation begins). The crew can also activate wing protection when conditions are favorable for airframe icing (used as anti-ice to prevent accumulation).

Wing protection operates automatically on aircraft with primary automatic systems.

757-200PF: No Ice Detector

Interestingly, my airline’s 757 fleet does not have ice detectors. Company procedures (similar to the examples above) ensure the aircraft is protected in an icing encounter.

Is ice protection just a winter thing?

Aircraft icing can occur year-round at any latitude, even at the equator. It might be 95°F (35°C) at the airport, but clouds 20,000 feet above can contain water droplets supercooled below freezing. When aircraft fly through cold clouds, it’s important for flight crews to use ice protection systems to protect wing leading edges and engine inlets.

Further Reading

Aircraft De-Icing: Why They Spray Aircraft

Aspirated Total Air Temperature Probe

Collins Aerospace Ice Detection and Protection Systems

Like this:Like Loading…